A Lethal Cocktail

Stirred in the Tees

as Dredging

Gets Underway

Image courtesy of Stan Rennie

Scott Hunter

13 October 2022

Ever seen a polluter at work? You are about to.

The image above was the scene on Tuesday 11 October in the Tees Estuary, where JCBs are being used to move contaminated sediment that has been dredged from the river bed. The particular area being treated here is one where the licence to dredge prohibits disposal at sea, so toxic is the mixture of chemicals contained in it. The most toxic part of the most polluted estuary in the UK.

A clearer view of what is happening is available on video here.

Tees Valley mayor, Ben Houchen announced on 1 September, the day that dredging work for the South Bank Quay began,

“As dredging work for the South Bank Quay begins, we will be holding ourselves to the highest standards in everything we and our partners do, far exceeding the baseline legal requirements. All of the material recovered from this dredge will be disposed of safely on land. Let me be clear, not a single gram of dredged material will be disposed of in the river or out to sea. Everything is being removed from the river and disposed of on land.”

The dredge was commissioned by main contractor Graham Construction and has continued seven days a week since the beginning of September.

“Not a single gram of dredged material will be disposed of in the river or out to sea”

As the footage clearly shows, that claim has turned out to be a bit optimistic. Sediment, lifted from a barge is spilling out from the JCB buckets as it is loaded into waiting trucks. But why the prohibition in the first place? What exactly is in that sediment?

To find that out we consulted the marine licence application submitted by the South Tees Development Corporation which contains details of what they found when they sampled the sediment at the location you see in the photo.

What they found in Borehole 34

Readers familiar with the area may recognise the MGT power plant in the background. Sampling in that vicinity (via borehole 34) produced the following results:

Dissolved metals

Cadmium, chromium, copper, mercury, lead and zinc all exceed government guidelines for safe disposal at sea (known as Cefas Action level 2). For mercury and zinc, the levels found are more than four times the permitted limits.

22 hydrocarbons (PAHs) were tested for. These substances are not household names, but they’re all highly toxic. Here, the government guidelines do not provide us with limits. So, we refer to international ones (known as CSQG) instead.

Here are the CSQG upper safety limits for a selection of these hydrocarbons measured in parts per million:

Naphthalene 391

Fluorene 144

Phenanthrene 544

Pyrene 1398

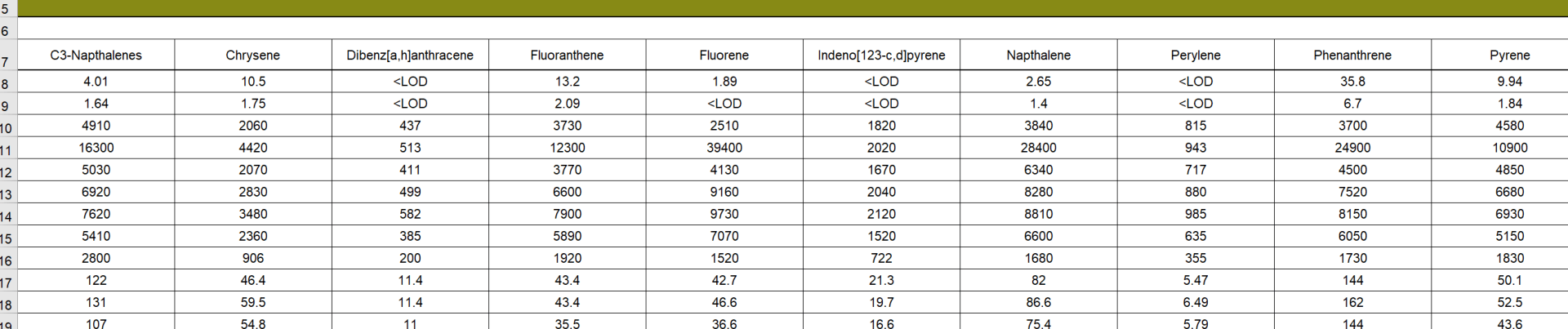

And here’s a segment of the table of sampling results provided by the South Tees Development Corporation to the licence issuing authority, the Marine Management Organisation. Line 11 shows the levels obtained at 1m below the sediment surface:

Source: South Bank Quay Marine Licence Application MLA/2020/00506, Results Template MAR00856

Selected highlights from the table:

Pyrene, at 10900ppm, exceeds the international safety limit by eight times.

Phenanthrene, at 24900, is 46 times the limit

Naphthalene, at 28400, is 72 times the limit

Fluorene, at 39400 is 273 times the limit

We should add that, not only are contaminant levels very high across the board, but more contaminants are available. Pyridine, for example, does not appear on the list because it is not tested for.

The Defra partner agency responsible for monitoring sediment contamination, Cefas, does not tailor its sampling requirements to local conditions. So, despite the fact that pyridine is always found in areas where there are coke ovens (there were at least three coke batteries on what is now the Teesworks site), Cefas does not require that it be included in the list of substances to be tested for. How many more toxins are undiscovered in that sediment is anyone’s guess.

Official Response

We began by contacting both the Tees Valley Authority and the main contractor, Graham Construction. The response?

Tees Valley Combined Authority – no response

Graham Construction – no response

Then we moved on to the government agencies.

We asked Cefas if the use of JCBs was consistent with the terms of the marine licence. Response? No response.

We asked the Environment Agency if they were aware that the dredge material was being handled in this way and if their officers had visited the site. They advised us that they are looking into it but told us that the relevant people were out on site visits, so they could not yet give us a full reply to our questions.

As for the Health and Safety Executive, we informed them that eyewitnesses have stated that workers on the site were wearing standard hi-viz and hard hat, but no other protective clothing. They are also looking into this.

And so on to the Marine Management Organisation (MMO) who issued the marine licence. We sent them a video segment and asked the following questions:

1. Is the MMO satisfied that this removal method is consistent with the terms of the licence?

2. Does this method adequately prevent recontamination of the water body?

3. Is the MMO prepared to suspend the licence to dredge until it is satisfied that the dredged sediment is being safely handled?

Their response:

“The video does not show dredging activity. The dredged material is deposited to a barge (using the closed bucket system) alongside the dredging pontoon. The barge is then moved alongside the platform shown in the video. The video shows the JCB on the platform moving the sediment from the barge to the trucks for landfill disposal (the video shows some mud falling on to the platform rather than the sea). There is no requirement in the marine licence for this section of work to be closed bucket as this piece of machinery is not actively dredging the sediment up.”

This is true. The video segment we sent them shows JCBs on land moving contaminated sediment around and spilling amounts of it as they do so. And if ‘mud’ is falling on to the platform, then how is that being cleaned up? Do workers have to walk on that platform? What is to prevent rainwater from washing spillage straight back into the river?

It is also true that the dredged material is being deposited to a barge using the closed bucket system. Here it is in action (although the video gives a clearer impression):

The stuff coming out of the top of the closed bucket is contaminated water, and that bucket is in operation 24 hours a day. So, there are still a few issues to deal with. One is the suitability of closed bucket dredging for the task in hand in the Tees. Another is the need to protect the water body beyond the immediate area of the dredge from contamination.

We recently consulted an expert who is familiar both with the Tees and its sediment history, and also with available dredging methods. Their opinion is that closed bucket dredging is simply not safe enough to remove toxic material from the bottom of the most contaminated estuary in the UK. There is far too much spillage.

In addition to this, there is a need to curtain off the dredge area to prevent resuspended sediment from leaching into other areas of the estuary. No such curtaining is in place, as is evident from the video.

Our expert’s opinion was that the safest way to remove this sediment would be to use what is known as a cutter suction dredger, or CSD. This dredger has a cutter to loosen the sediment and a suction pipe that immediately sucks the dredge material up directly from the estuary bed without having to drag it through the water, and can, if necessary, deposit it directly on land.

To be fair, the MMO did not specify that a closed bucket dredger should be used. They left that decision up to the Tees Valley Authority and the main contractor, Graham Construction, neither of whom felt the need to defend their actions when we contacted them.

Oddly, however, we find that the Tees Valley Authority hired consultants Marico Marine, who assessed navigation risks of the proposed dredge. Their conclusion, delivered in April 2022, and contained within the Marine Licence Application documents, was that

“The proposed changes to dredge methodologies and areas have been re-assessed, and it is concluded, based on the quantified assessments of navigational risk for both the original NRA, and a subsequent internal review of using a Cuter Suction Dredger only, that overall navigational risk during the construction phase of the Tees South Bank Project will decrease …” [sic]

So both on the grounds of safe removal of sediment, and navigational safety during dredging work, a CSD is recommended.

The Highest Standards

Presumably Marico Marine was paid for the advice that was subsequently ignored. Presumably that was not included in ‘the highest standards’ that the Tees Valley mayor was so keen to trumpet at the beginning of September. Precisely which highest standards the mayor is holding himself to are somewhat obscure, however. Certainly, his media team withholds information to a very, very high standard, but that seems to be about it.

And the MMO has looked at the some of the footage and concluded that this is good enough. Good enough for the Tees where, as we have reported before, safety standards on the dumping of toxic waste can be dispensed with.

The site of this dredge is around six miles from Saltburn, where, three weeks ago, Defra reported that bad weather was responsible for razor clams and mussels washing up on the beach.